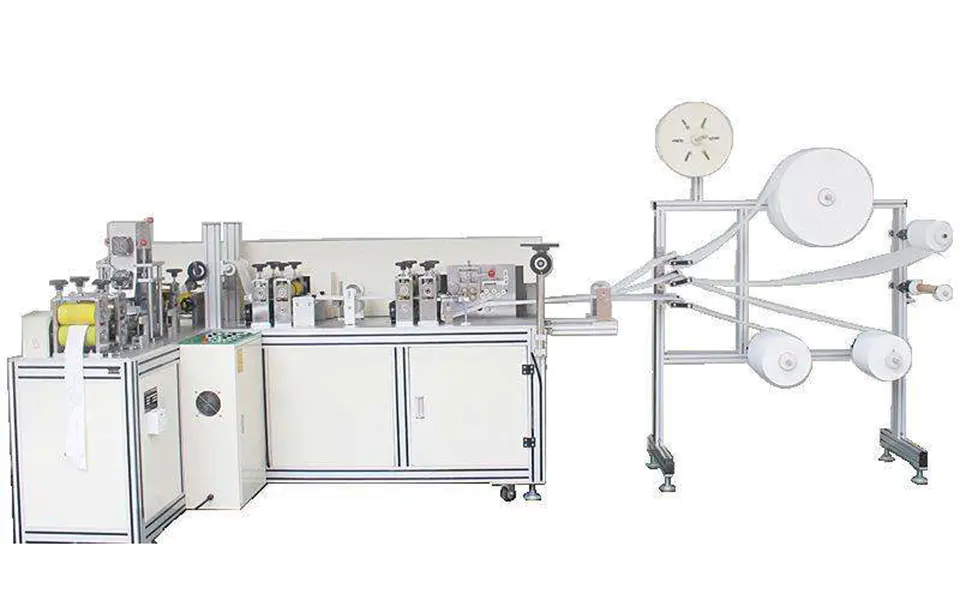

Full automatic flap disc machine can automatically upload backing,detect backing,quantitatively feeding,flap cutting and setting,shaping and automatically download finished flap discs with high automation.

The equipment adopts PLC to control the human-machine interface, which is easy to operate, saves labor and reduces cost.

The equipment adopts the rotary multi position rotary table mechanism, with stable station conversion, accurate positioning and high efficiency.The equipment can be placed in a variety of different types of backing pad, with high-strength aluminum alloy material, stable and durable, easy to load and unload blades.

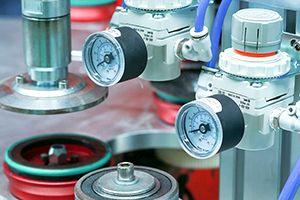

The equipment gluing system adopts the internal water circulation constant temperature control system, the glue pump structure design is reasonable, suitable for different materials of glue, convenient, efficient, stable and fast.

During flap setting,there is an imported photoelectric switch to detect backing and belt.Backing vacant working plate and backing without glue coated can be automatically detected and filtered with stable precision.saves time.

Flap setting angle and flap length can be precise adjusted,The head adjustment translation is equipped with a scale, which can adjust the head accurately and efficiently according to the display parameters.with easy and convenient operation.

High degree of automation, single person can complete 2sets machine operation, liberate labor force, save labor cost for you.

High production efficiency, the machine can produce 900-1400 pcs/ hour.

High utilization rate of production materials, free setting of adhesive and sand belt, serving large and medium-sized enterprises.

Very low defective rate. After the machine is adjusted, the defective rate is close to 0%, which makes your production more worry free.

Technical parameter:

|

Name |

High-speed flap disc machine |

|

Model |

FHGQ-180 |

|

Size of Main-body |

1900mm*1590mm*1400mm |

|

Size of Glue pump |

1100mm*650mm*1500mm |

|

Speed |

900-1400pcs/hour |

|

Size of Feed belt |

1000mm*400mm*1450mm |

|

Plate |

Ten |

|

Loading and unloading turntable |

Eight |

|

Voltage |

3 phasa 4 wire 380v+N 50HZ/60HZ |

|

Power |

6-8KWAccording to different configuration |

|

Motor |

Imported Panasonic servo motor |

|

Power supply |

Pneumatic,electric |

| Glue pump specifications | 280KG |

| Glue coated | 3-30g(can be adjusted) ±0.1g |

| Flap quantity |

Can be set at any angle of 360° (20-200pcs/product) |

| Size of backing pad | Φ75mm~Φ180mm , T27/T29 |

| Backing material | Fiberglass.iron,plastic |

| Belt width | Double flap,flap width 20mm-40mm |

| Flap length | 11mm-25mm |

| Control system | Relative positioning+CAM principle+Pendulum principle |

| Glue system | Constant voltage conversion+Intellgent thermostatic water circulation system |

| Operation | One people can operation 2 sets |